Grey goods inspection on a glass table equipped with high-quality tube lights in compliance with 4 points American standard.

Sending grey to the dyeing unit with all required parameters like colorfastness, residual shrinkage, pilling standard, appearance after first 3 washes, feel of the fabric, shining, etc. informed to dyer prior to the dyeing process.

The dyed finished fabric is cut by our cutting masters as per the required length and width, depending on the size and type of bed sheets/ pillow covers that have to be made.

The cut fabric is then sewn into bed sheets and pillow covers by our highly experienced squad of tailors.

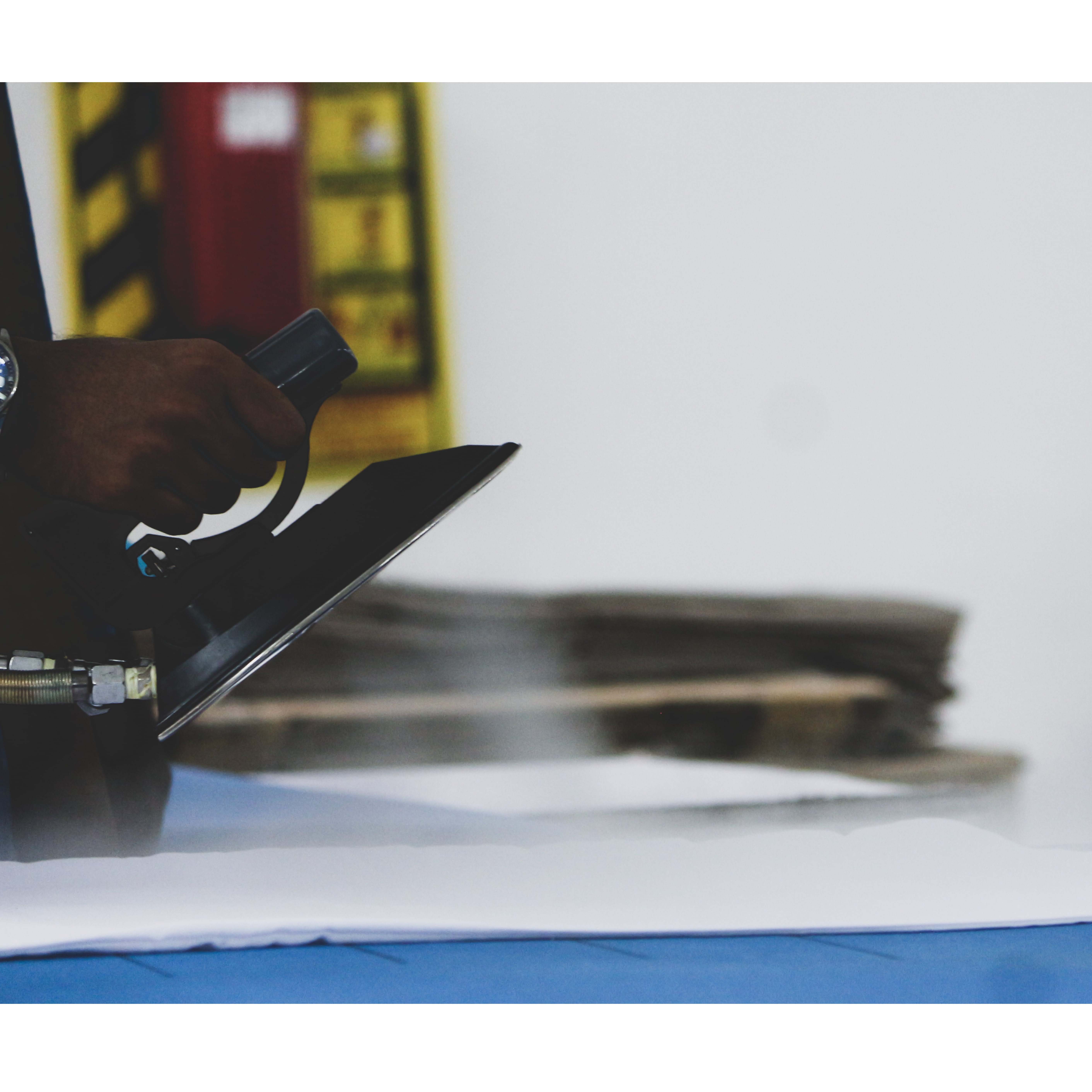

After the stitching is done, the sheet sets and pillow covers are sent for trimming. Our staff carefully trims the threads that are pointing outwards and also checks the bed-sheets & pillow covers for any sorts of defects (Contamination, Colour stains, Oil stains, Handling stains and Holes). These are then sent for ironing.

In this final step, once the materials are ironed, they are again re checked by our inspection experts and supervisors just before being packaged. A sample is sent from our packaged goods to our buyers for quality check and after the buyer's approval, the entire order gets shipped to wherever the buyer needs it to be. The buyer receives the shipped goods within the expected time period and sells it to his/her own customers.